Problem-solving

E-commerce

UX Design

Story 3: E-commerce and inventory.

I have always enjoyed organizing and classifying things, both in my personal and professional life. I’ve probably been super annoying to people in various situations, and I apologize to all of them publicly because I now know how important it is to navigate through messy situations before they can be organized. Some of the experiences that taught me to be comfortable with ambiguity and the messiness of processes include working with change orders in construction, working at my family business, immigrating to Canada, and working with warehouse and inventory. When it was time to organize things at the end or beginning of the year (whether files or goods), I really enjoyed it. Unlike my colleagues, it wasn’t a burden for me. I was excited by the challenge of fixing issues, both physically and virtually. This story is about my observations regarding software in e-commerce, shipping, and inventory management.

Receiving orders

I had some experience dealing with orders in Brazil in the shoe industry, but the software we used was incredibly outdated, and the process relied mostly on emails and spreadsheets—very manual, very messy, and not demure. Here, I worked with Shopify. It’s one of the best platforms I have used so far, to say the least. I was able to start using most of its features without any instruction, and for more complex tasks, I just referred to the how-to guides and Shopify Academy.

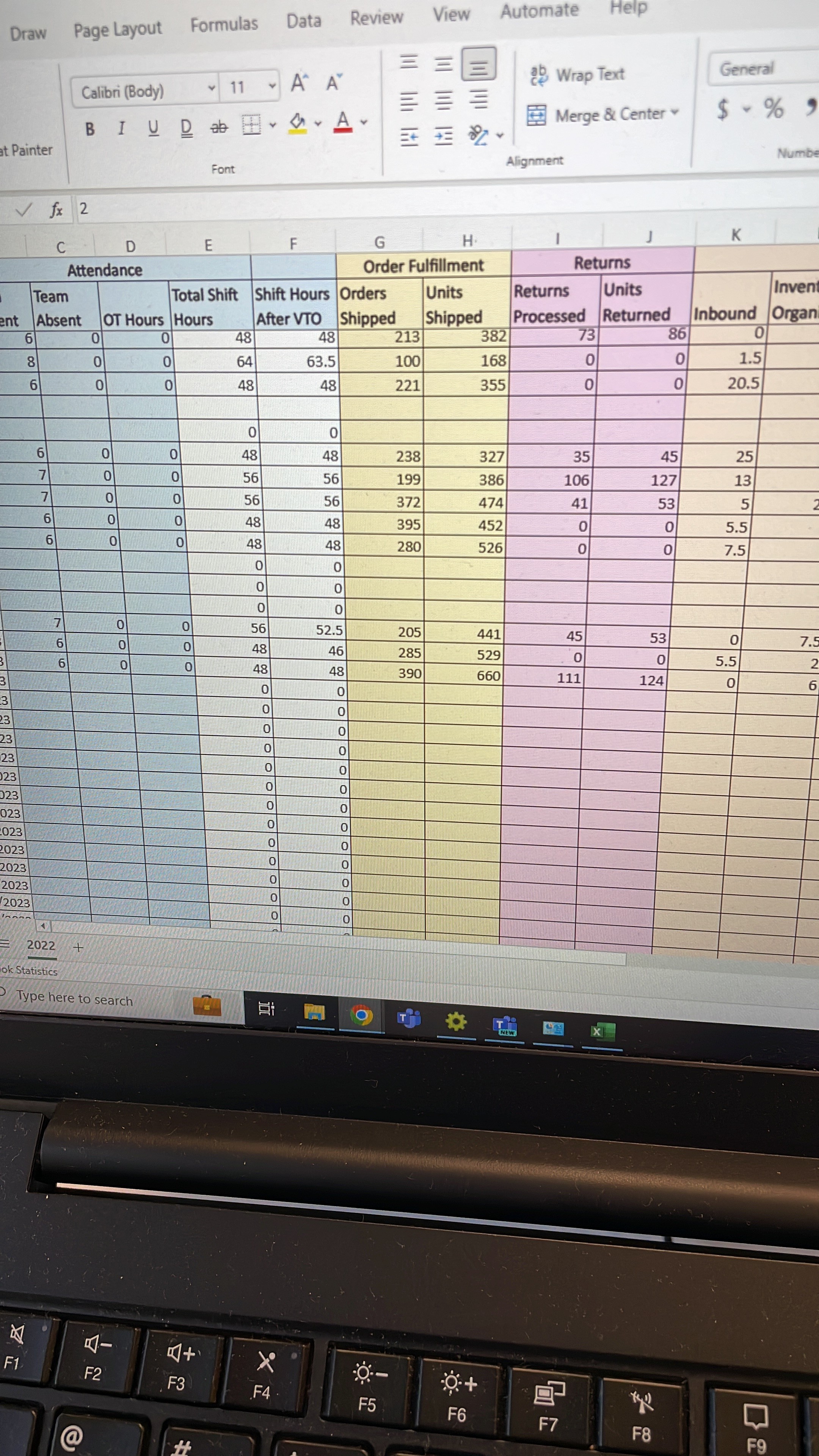

However, at the time, Shopify didn’t allow us to track and manage incoming inventory. Sometimes, when an e-commerce site supports pre-sales or any product that isn’t physically and readily available, things can get really messy. To organize this chaos, and unsurprisingly, spreadsheets were created to track the numbers. I’m not against spreadsheets—in fact, I love them, as I’m also an engineer. But spreadsheets require manual input and updates, often by people who are already busy, thus being a fragile point in the process for mistakes to occur. We encountered several issues with this approach, and at one point, we couldn’t fulfill orders because there wasn’t enough physical product available. Errors in item counts and discrepancies between the spreadsheet and Shopify’s inventory numbers became a major problem.

People started getting upset and looked for someone to blame, but that’s never the best way to identify the root cause and fix the problem. I don’t think it was anyone’s fault. Instead, it was a design issue—perhaps not exactly a Shopify design issue, but a design problem in how we planned and handled the entire process. Eventually, we managed to solve this by ordering more products and correcting the spreadsheets. However, I was pleased to see later that Shopify now supports incoming inventory tracking on its platform.

Shipping orders

For shipping and verifying the accuracy of items in specific orders, I had the opportunity to work with Shipstation software. While it’s a good platform, it gave our team constant headaches. Sometimes, integrations aren’t thoroughly done, or people aren’t fully aware of the consequences of their data input.

To scan a product and verify it is the correct one for an order, Shipstation uses a barcode called the Universal Product Code (UPC). This information either comes from its integration with Shopify or is manually inputted in Shipstation’s Product feature. The people responsible for entering this information weren’t working on the warehouse floor and didn’t had the opportunity to spend some time scanning the products. When the team members began constantly complaining about not being able to scan the products correctly, we investigated. The impact of not scanning a product correctly is that the associate must verify it manually, which can lead to sending the wrong product (which happened several times). This results in frustrated customers, inaccurate inventory, canceled or returned orders, and less trust in the brand.

While investigating, we identified two issues:

For some products, the UPC was displayed in scientific format. For example, the code 456789087654 appeared as 4.57E+11, preventing the system from recognizing it as the same code.

For some products, the UPC in Shopify was copied and pasted, so all variations of a product shared one UPC.

We decided not to fix these issues ourselves but instead trained the most experienced associate team members to do it. This gave them speed and agency over the process, as they were the ones scanning (sometimes up to 1,200 orders a day) and noticing the problems first. The people who inputted the data weren’t to blame, as they didn’t understand the impact or the importance of these codes. Instead of blaming, being curious about the issue was a better approach to solving it.

Reconciling inventory

Before inventory was handled solely through Shopify, we used Xorosoft, which was integrated with both Shipstation and Shopify. This was a more complex system, as it dealt with more than just inventory and shipping, but I’ll focus on the inventory feature. During a full inventory recount and reconciliation, the software created duplicate orders for the same customers. The error was quickly identified because when the team was picking and packing items for orders, several products were suddenly unavailable. All the professionals involved did their best to analyze and fix the issue, but unfortunately, we had to stop shipping orders for a while.

Although we had several hypotheses, we never identified the root cause. We had long meetings with Xorosoft support, who did their best to help, but to be honest, it felt like we didn’t fully understand each other. The inventory specialist and team leaders had to check more than a thousand orders manually to determine whether they had already been shipped. Supporting spreadsheets were created, but since the e-commerce site was active, quantities and orders were changing daily. Eventually, we managed to check all the orders from a specific time period, but the real issue was never identified. I still suspect some backend configuration of the integrations crashed, but I can’t be sure. The team ultimately decided to stop using Xorosoft and manage all inventory exclusively through Shopify for simplicity.

Lessons

What I learned from these situations is the importance of humility and paying attention to everyone involved in the process. Sometimes, people on the floor notice important issues early, long before they escalate, so listen to them and investigate. Also, finger-pointing does more harm than good because once you start blaming others, they lose trust in you and may stop communicating when they identify new problems. And again, these issues are rarely only the software company’s fault as well; they’re usually design issues or overlooked situations, as no platform can predict every problem or user need although from a UX design and product perspective, they should try their best to. Sometimes, the only way to improve a system is when an error occurs, and people start paying attention—I feel like nowadays as long as we can learn fast with our fails, that's the way. After all, we’re not talking about life-or-death situations in this specific case, just products. I just hope others learned the same lessons I did and avoid making the same mistakes after those experiences.